Click to enlarge

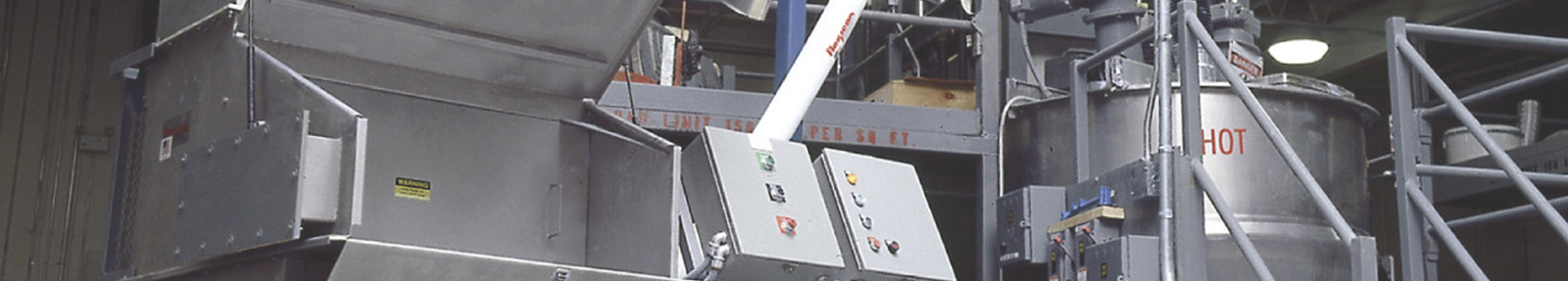

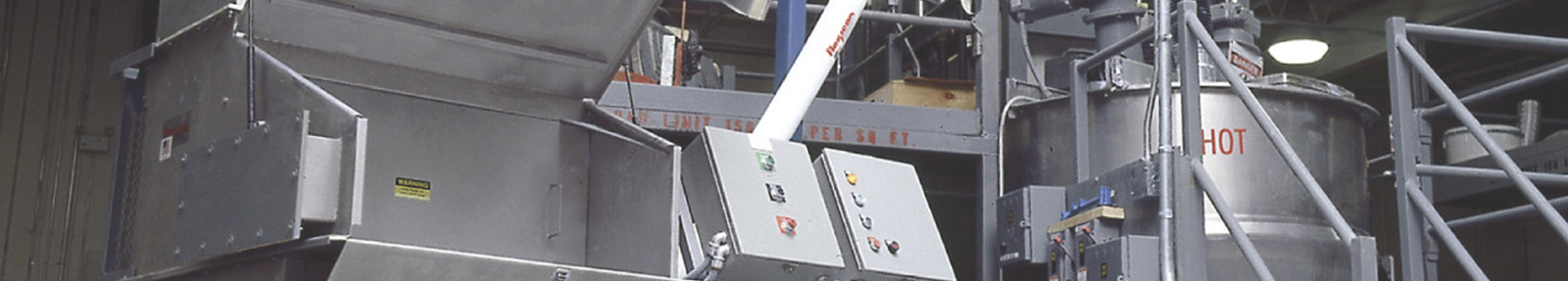

Click to enlargeOperator empties bags of fumed silica into bag dumping station dust-free while flexible screw conveyor feeds line material into a process vessel

Click to enlarge

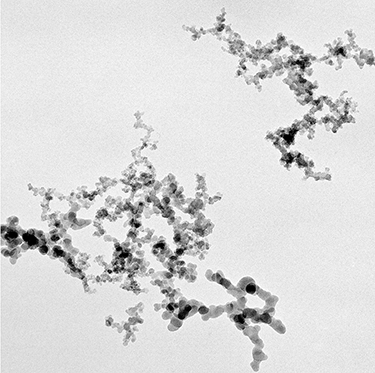

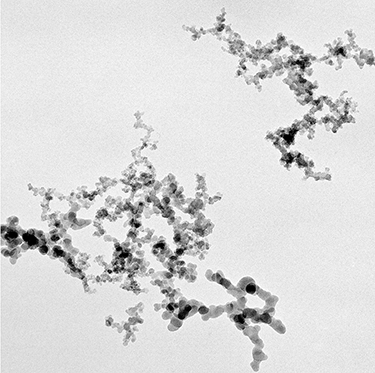

Click to enlargeElectron micrograph of fumed silica at 100,000X magnification shows loose packing of chain-like aggregates.

Click to enlarge

Click to enlargeBag dump station, dust collector and flexible screw conveyor are self-contained on a caster-mounted frame which is wheeled between process vessels requiring 300 lb (135 kg) batches of fumed silica.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge