Click to enlarge

Click to enlargeFLOW-FLEXER® plates raise and lower the bag to promote complete evacuation.

Click to enlarge

Click to enlargeAn inclined and a horizontal flexible screw conveyor transport gypsum powder from the bulk bag discharger to the rotary treater.

Click to enlarge

Click to enlargeForklift loads a bulk bag onto the discharger frame, which is fitted with dust collector (right).

Click to enlarge

Click to enlargeIris valve prevents uncontrolled bursts of material and dust when bag spout is untied.

Click to enlarge

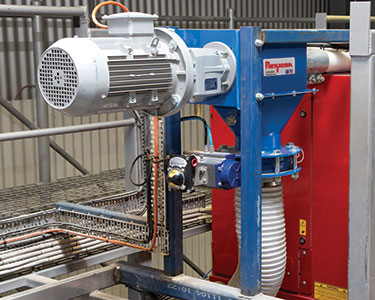

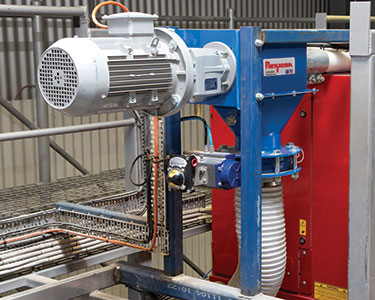

Click to enlargeHorizontal flexible screw conveyor transports the powder through a transition adapter and downspouting, to the rotary treater inlet. Motor at the discharge end drives the conveyor.

Click to enlarge

Click to enlargeGypsum powder moves from the bulk bag discharger through the inclined flexible screw conveyor which transitions to a horizontal flexible screw conveyor discharging into the red pelletizer.

Click to enlarge

Click to enlargeCoated seeds from the pelletizer

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge