Click to enlarge

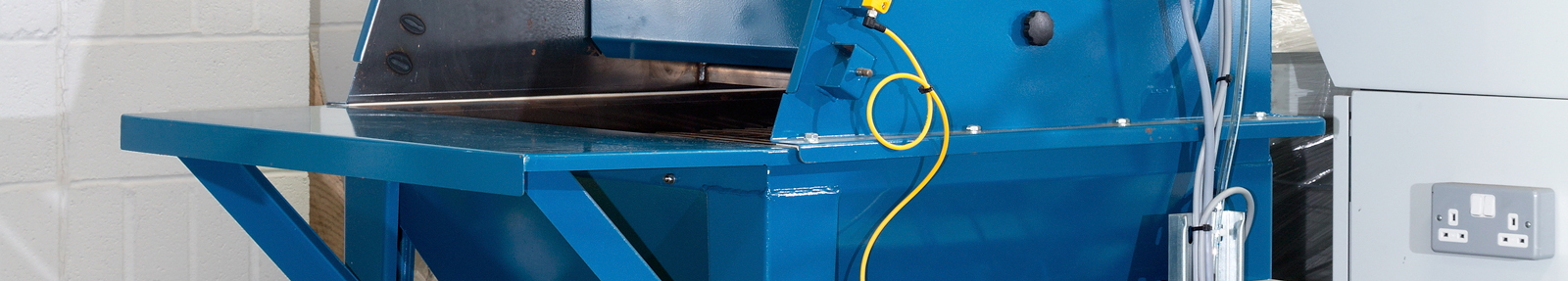

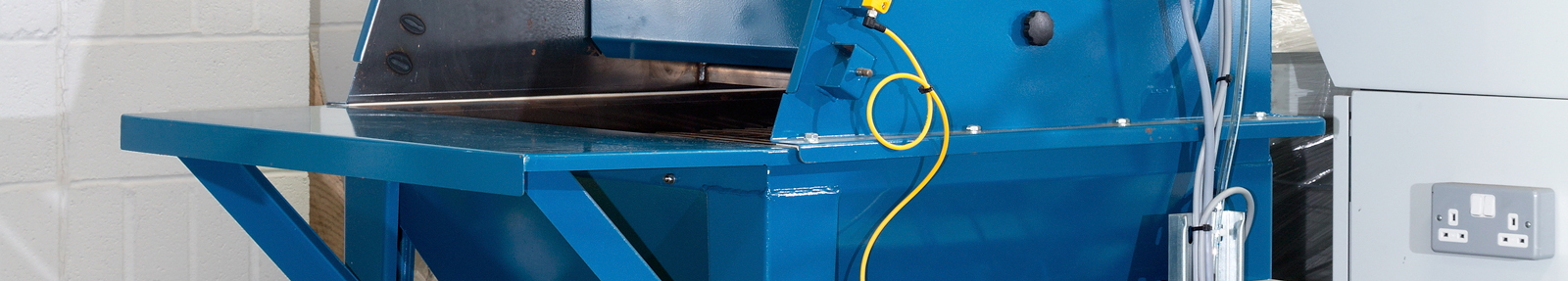

Click to enlargeSilicon powder and additives are manually emptied into the bag dump station and floor hopper. The station includes a bag tray support and dust collection through two cartridge filters. Powders flow from the hopper outlet through a pickup adapter into the pneumatic conveying line.

Click to enlarge

Click to enlargePowders move from the bag dump station through the pneumatic conveying line to the filter receiver (rear) in the main processing area. Fully enclosed system prevents the escape of dust.

Click to enlarge

Click to enlargeFrom the pneumatic line, the filter-receiver separates the silicon powder from the air stream before the powder enters the receiving hopper and is delivered to a slurry tank. A reverse pulse jet system cleans the filter cartridges at timed intervals.

Click to enlarge

Click to enlargeNexeon produces silicon anodes that improve performance of lithium-ion batteries.

Click to enlarge

Click to enlargeSilicon powder is the main ingredient in Nexeon's manufacture of silicon anodes.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge