Click to enlarge

Click to enlargeThe automated bulk bag filling station fills bulk bags with up to 352,000 lb (160,000 kg) of abrasive materials per eight-hour shift.

Click to enlarge

Click to enlargeSkid-steer loader deposits mineral sands into the 88 ft3 (2.5 m3) capacity hopper while the screw conveyor moves the material to the bulk bag fill head.

Click to enlarge

Click to enlargeThe Swing-Down® fill head pivots to a vertical position, allowing the operator to safely and rapidly attach bag straps to filler latches while standing on the plant floor. Pushing one button inflates the material inlet against the bag spout, and initiates all automatic bag filling functions.

Click to enlarge

Click to enlargeThe filled bag and pallet move out on the roller conveyor and are removed for shipment.

Click to enlarge

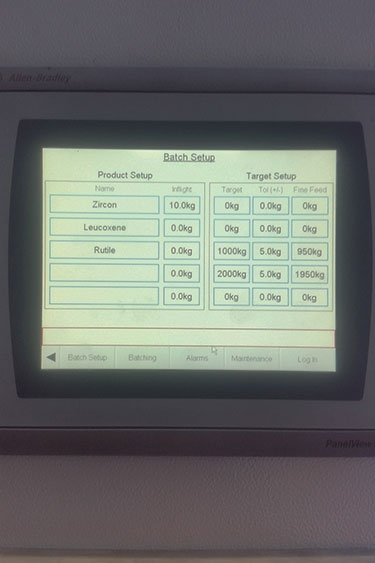

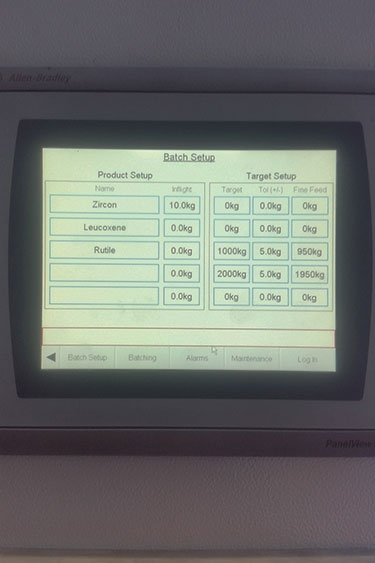

Click to enlargeA touch-screen interface on the PLC allows program setup and activation of filling cycles.

Click to enlarge

Click to enlargeA pneumatically-operated product sampler captures a 4.3 oz (142 g) specimen from the material stream for product quality documentation.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge