Click to enlarge

Click to enlargeBlended material flows from a bulk bag into the floor hopper of a flexible screw conveyor, which discharges into a vibratory separator discharging into a packaging machine.

Click to enlarge

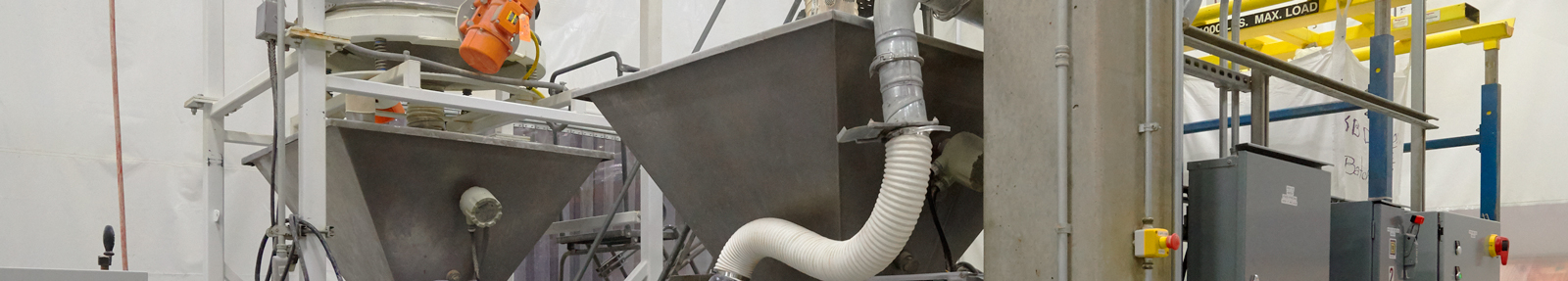

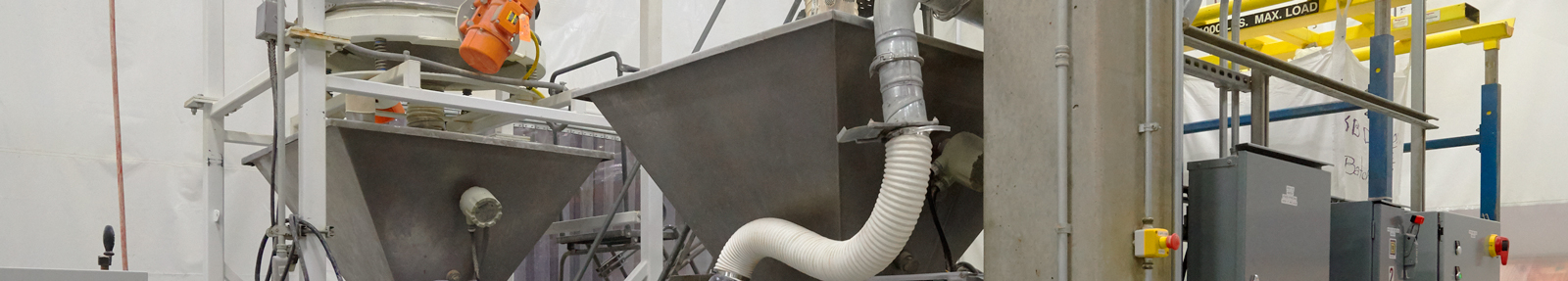

Click to enlargeThe company's second bulk bag discharger, with screener integrated into the frame, discharges blended material into a hopper above a packaging machine.

Click to enlarge

Click to enlargeA forklift places the bag and lifting frame onto the Bulk-Out® BFF bulk bag discharger frame.

Click to enlarge

Click to enlargeAn operator secures the bag spout with a Spout-Lock® clamp ring positioned atop a Tele-Tube® telescoping tube that lowers, keeping the spout taut to promote flow and total evacuation

Click to enlarge

Click to enlargeMaterial exits the conveyor below the point at which it is driven, preventing contact with seals or bearings.

Click to enlarge

Click to enlargeMaterial discharged from the flexible screw conveyor is screened before being fed to a packaging machine.

Click to enlarge

Click to enlargeKB Ingredients packages and ships blended ingredients to the baking and food processing industries.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge