Click to enlarge

Click to enlargeA 30 m (98.4 ft) long conveying line transfers wet, abrasive mica powder from the wet process on the floor below into the filter receiver which separates the material from the conveying air.

Click to enlarge

Click to enlargeThe hopper below the filter receiver receives the wet mica and discharges it to a drying system followed by separation by particle size.

Click to enlarge

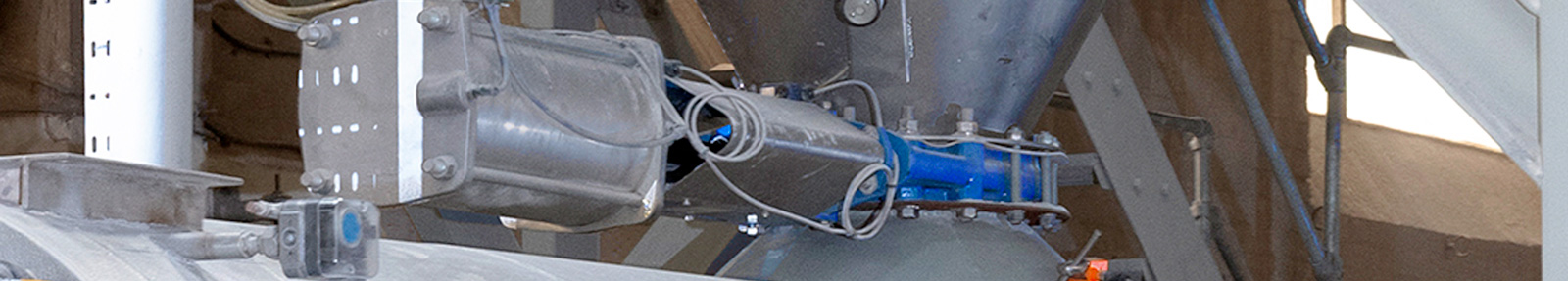

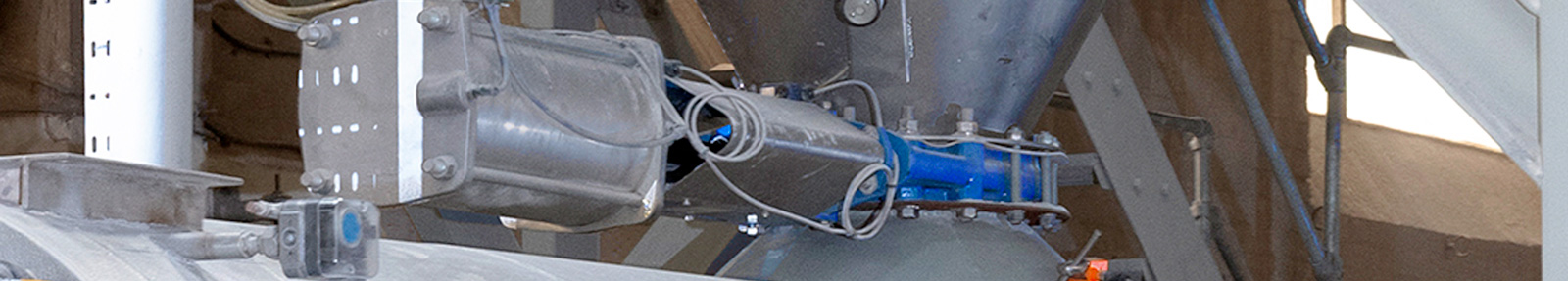

Click to enlargeReplacing a failed pneumatic pipe elbow, the HammerTek deflection elbow minimizes wear of the elbow wall as the spherical chamber gently deflects the incoming material around the bend.

Click to enlarge

Click to enlargeFinal milled muscovite material has gone through size reduction, pneumatic conveying, drying and sieving steps.

Click to enlarge

Click to enlargeLKAB's MicaFort product is used as a mineral filler for paint and coatings and other applications.

Click to enlarge

Click to enlargeLKAB Minerals have processed mica at their Derby facility since the 1950s.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge