Click to enlarge

Click to enlargeBulk bag weigh batch dischargers equipped with hoppers and flexible screw conveyors, elevate ingredients 30 ft (9 m), metering precise batch weights into a ribbon blender under PLC control. The automated, dust-free system replaces manual dumping of 50-lb (23 kg) bags.

Click to enlarge

Click to enlargeTwo flexible screw conveyors transport ingredients to a ribbon blender which discharges into a third flexible screw conveyor that elevates the blend 30-ft (9 m) through the ceiling to a smaller blender on the second level.

Click to enlarge

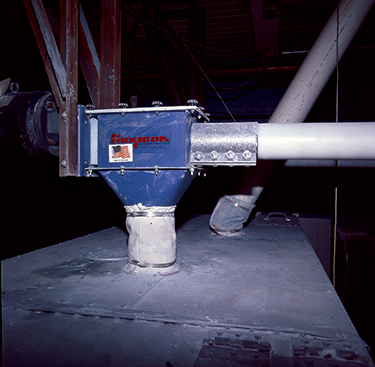

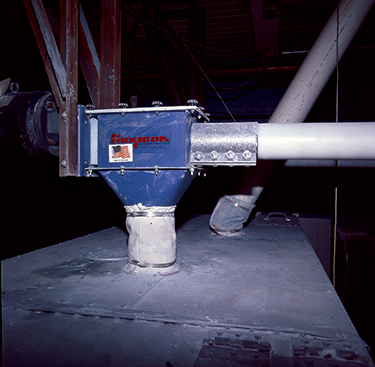

Click to enlargeIngredients are fed into a ribbon blender by a flexible screw conveyor through a discharge transition adapter.

Click to enlarge

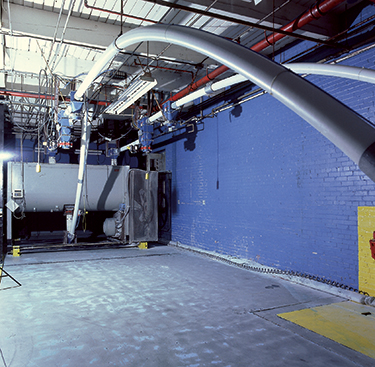

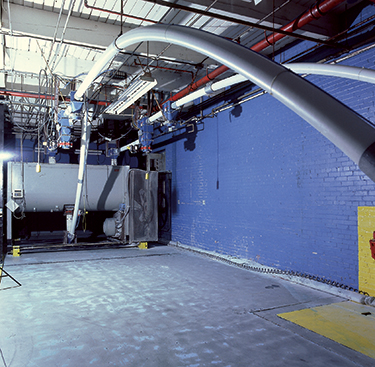

Click to enlargeA ribbon blender discharges the blend into a flexible screw conveyor that elevates the mix 30-ft (9 m) through the ceiling to a smaller blender on the second level.

Click to enlarge

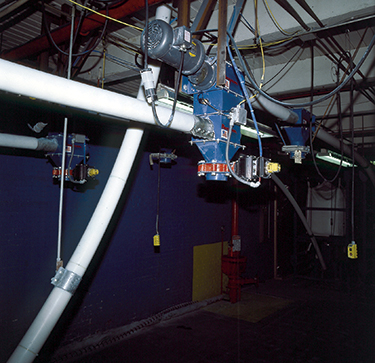

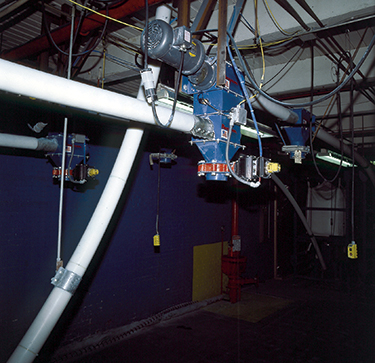

Click to enlargeCharging adapters join 30-ft long (9 m) flexible screw conveyors from bulk bag unloaders to 10-ft long (3 m) conveyors, which will feed a second ribbon blender to increase capacity with a second batching line.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge