Click to enlarge

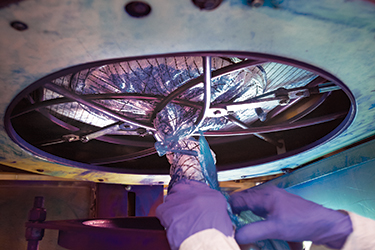

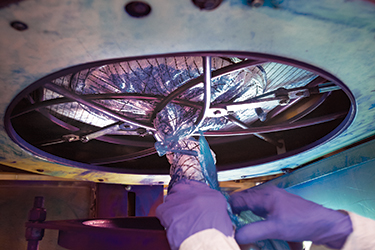

Click to enlargeA POWER-CINCHER® flow control valve regulates flow and permits closure of a partially emptied bag by concentrically cinching the spout.

Click to enlarge

Click to enlargeIn producing offset inks, pigments for each basic color (e.g., cyan, left and magenta, right) are transferred to a premix tank from a dedicated BULK-OUT® BFC bulk bag discharger and 32 ft (975 cm) long flexible screw conveyor, both from Flexicon Corp.

Click to enlarge

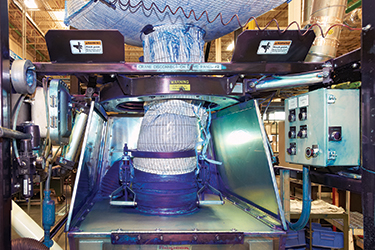

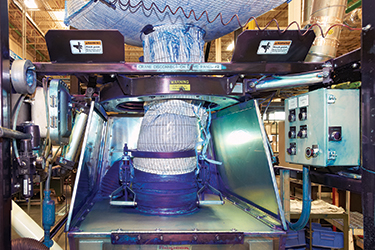

Click to enlargeAt the bag spout interface, a SPOUT-LOCK® clamp ring (left) and a TELE-TUBE® telescoping tube (right) eliminate dust and control flow. Also at right, FLOW-FLEXER® bag activator plates promote flow from the bag.

Click to enlarge

Click to enlargeOffset inks begin as CMYK (cyan, magenta, yellow, key [black]) pigments. Each powder is transferred by its correspondingly-colored bulk bag discharger system.

Click to enlarge

Click to enlargeNon-free-flowing pigment powders tend to cake, smear and create dust.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge