Click to enlarge

Click to enlargeDiatomaceous earth moves from the bulk bag through the hopper, flexible screw conveyor and downspout to a 300 gal (1136 l) tank before filtration of the wine. The completely enclosed system eliminates dust and reduces costs from manual dumping of small bags.

Click to enlarge

Click to enlargeDiatomaceous earth (D.E.) aids in filtration to remove solids from crushed and fermented grapes in 300 gal (1136 l) steel tanks before aging of the wine.

Click to enlarge

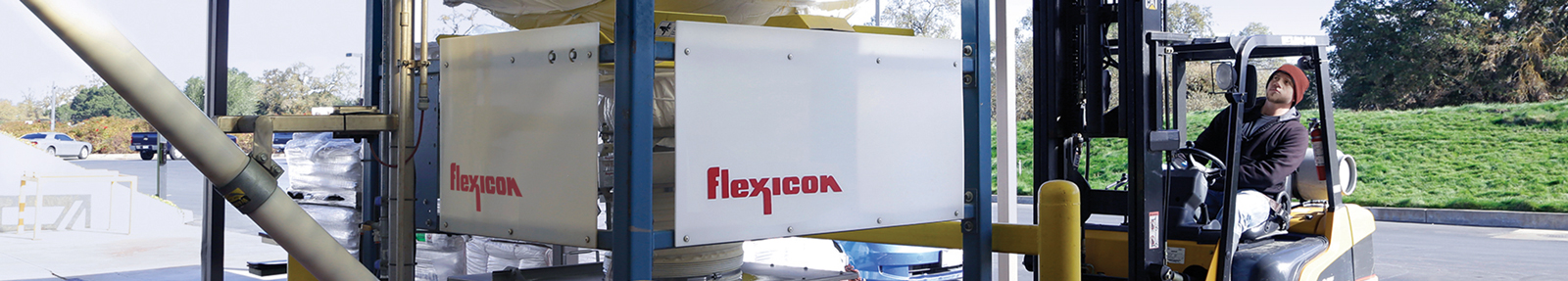

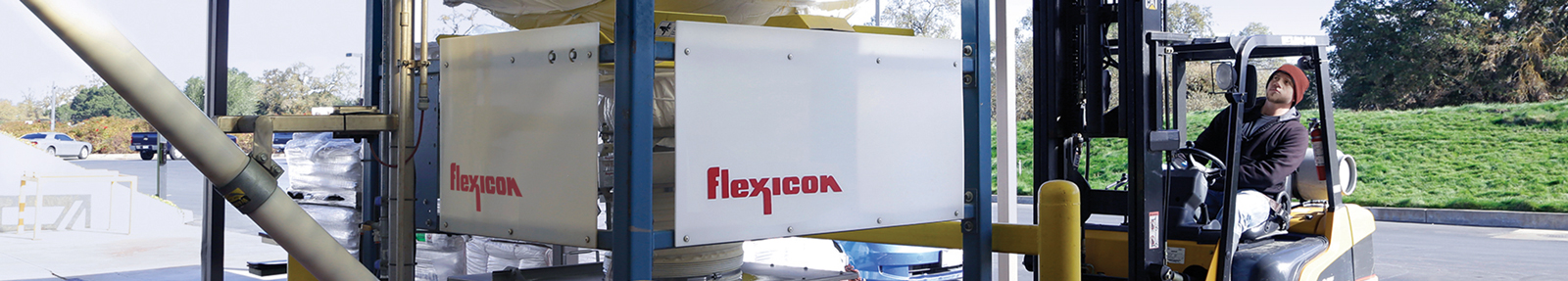

Click to enlargeForklift positions the bulk bag and bag lifting frame onto the cradle atop the discharger frame.

Click to enlarge

Click to enlargeDiatomaceous earth flows from the bulk bag through the dust-tight bag spout interface, hopper and flexible screw conveyor to the holding tank. FLOW-FLEXER® bag activators on opposite bottom sides of the bag promote complete discharge. Load cells allow automated weigh batching.

Click to enlarge

Click to enlargeThe bulk bag spout attaches to the discharger inlet by means of a SPOUT-LOCK® clamp ring positioned atop a TELE-TUBE® telescoping tube, which maintains a high-integrity sealed connection to the bag spout, virtually eliminating airborne dust.

Click to enlarge

Click to enlargeA light, powdery material, diatomaceous earth is prone to dusting when manually dumping it from 50 lb (23 kg) bags.

Click to enlarge

Click to enlargeLangeTwins Winery & Vineyards produces varietal wines using an automated process, while maintaining a five-generation tradition of quality.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge