FLEXICON® Flexible Screw Conveyors

Features

Economical to purchase, install and operate

A Flexicon flexible screw conveyor (also known as helix conveyor, screw conveyor, spiral conveyor and auger conveyor) does not require the internal and external components that can make other conveyors expensive to build and operate. The only moving part contacting material is the rugged flexible screw that resists wear and fatigue, resulting in extraordinary reliability and minimal maintenance.Because the screw and tube are flexible, and can be routed easily in any direction, the intake and discharge can be positioned where you need them, in situations that would be difficult, costly or impossible to satisfy with other conveyors.

High reliability, low maintenance

A Flexicon flexible screw conveyor has no internal bearings, cables, filters, chains, buckets, or other potentially problematic components to wear, break down, or require maintenance. The only moving part contacting material is a rugged flexible screw which resists wear and fatigue, and is driven by an electric motor.Even under a full load of moist, dense product — depending on application parameters — a Flexicon flexible screw conveyor can start and stop repeatedly with no binding or damage to the unit. The result is a conveyor without load limitations that runs dependably, boosting productivity while cutting maintenance.

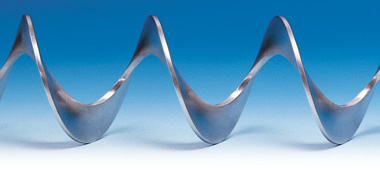

Only one moving part

The only part contacting material in a Flexicon flexible screw conveyor is the rugged flexible screw which is driven by an electric motor. As it rotates, the screw propels material and self-centers within the conveyor tube, providing constant clearance between itself and the tube wall.This simple design does not require cables, chains, disks, internal bearings, and numerous moving parts found in bucket elevators, rigid augers, drag chains, and/or aeromechanical conveyors—parts that can add initial cost, require maintenance, wear out, breed contamination, and/or break down.

Convey in any direction

Whereas many conveyors (such as rigid screw conveyor, bucket elevator, drag chain conveyor and aero mechanical conveyor designs) have limited angles of incline and/or straight-only conveying paths, Flexicon flexible screw conveyors can move material vertically, horizontally, or at any angle—over, under, or around obstructions, through small holes in walls or ceilings.

Gentle product handling and blending

Flexicon flexible screw conveyors can handle your products gently, because the flexible screw self-centers as it rotates. This can provide ample clearance between the screw and tube wall to prevent grinding, crushing, and other product damage.In addition, the gentle rolling action created by the screw prevents the separation of blends throughout the entire length of the conveyor.