Gently transport fragile bulk materials through smooth stainless steel tubing using low-friction polymer discs attached to stainless steel cables. This enclosed system offers gentle handling to prevent product degradation, flexible routing with modular components, and dust-free operation to maintain product integrity and plant cleanliness.

Learn everything you need to know about Flexicon® tubular cable conveyors.

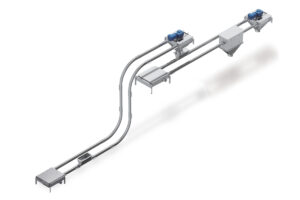

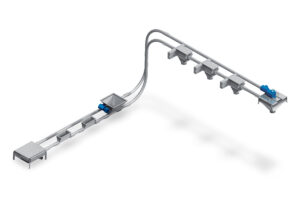

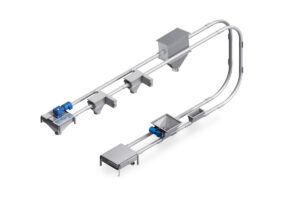

FLEXI-DISC® Tubular Cable Conveyors (also known as Disc Conveyors or Drag Conveyors) gently transport friable bulk materials through smooth stainless steel tubing using low-friction polymer discs attached to a stainless steel cable. The discs and cable are driven by a wheel at one end of a circuit and put under tension by a wheel at the other end. This design supports single or multiple inlets and outlets and the routing of conveyor tubing horizontally, vertically or at any angle, through small holes in walls or ceilings. Because components are modular, inlets and outlets can be added, removed or relocated, and the circuit lengthened, shortened or re-routed as needs change.

MATERIAL INLET

The Inlet Adapter funnels a metered stream of incoming material into the conveyor circuit to achieve the target feed rate.

TENSIONER

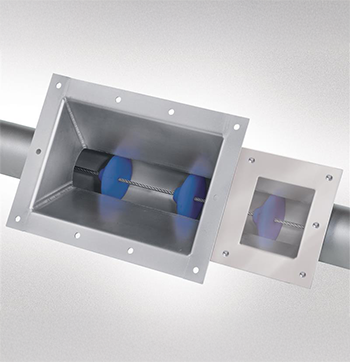

Engineered for performance and simplicity, the Cable Tensioner features a precision wheel that maintains optimal tension of the cable and disc assembly throughout the entire conveyor circuit. Its clear cover allows for easy monitoring of conditions in the tensioner. Flexicon offers manual and automated motorized models to satisfy a broad range of applications.

CABLE AND DISC ASSEMBLY

Discs formed from high strength, low friction polymers are attached to stainless steel cable gently propel material through smooth stainless steel tubing.

DRIVE

The Drive System powers a drive wheel that moves the cable and discs at a controlled, low speed throughout the conveyor circuit. When equipped with the optional discharge cone, it can function as the primary or final discharge point—offering flexibility for your system layout.

MATERIAL OUTLETS

Inline material outlets enable the conveyor to dispense material dust-free at one or multiple locations.

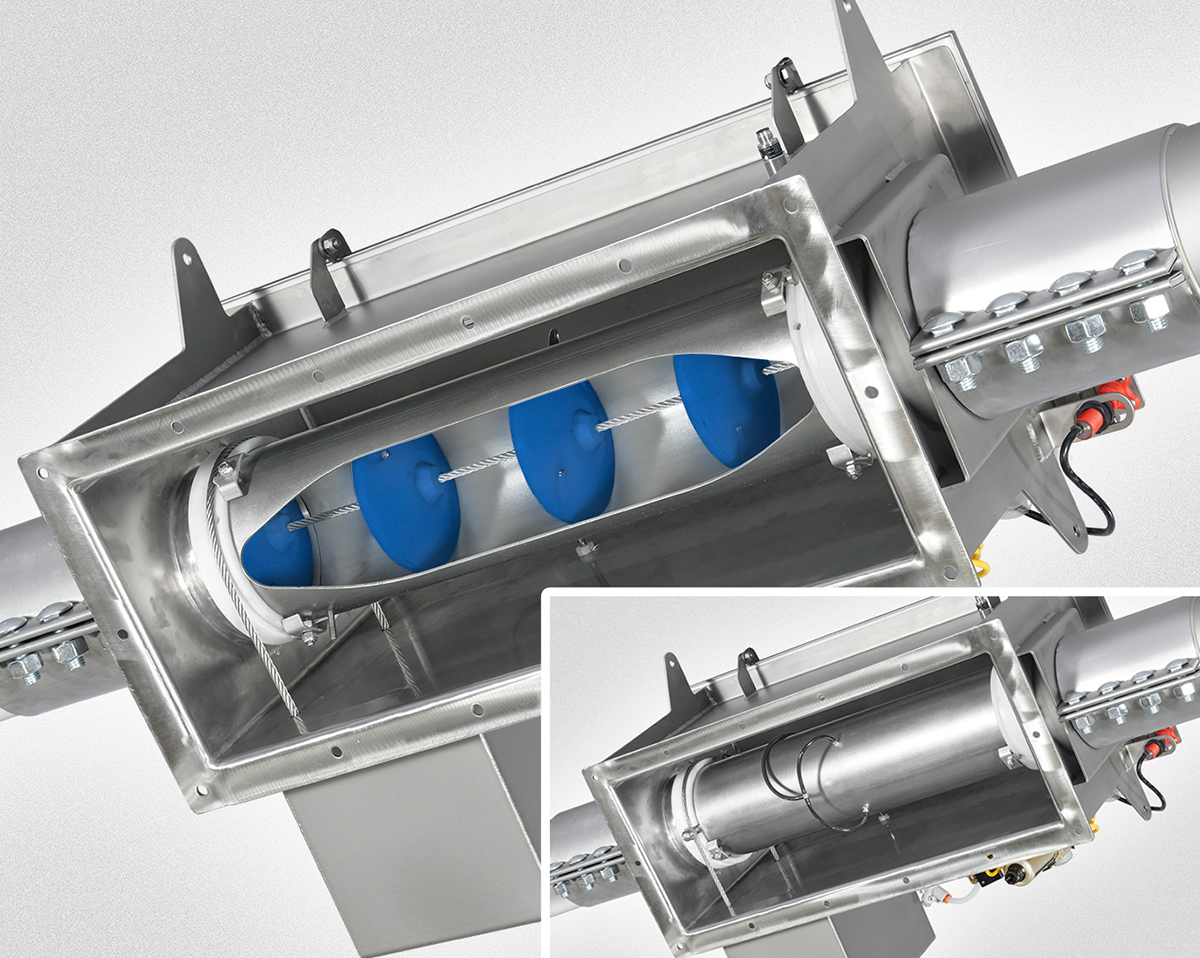

FLEXI-DISC CABLE-DISC ASSEMBLY

FLEXI-DISC Cable Disc Assembly is highly engineered to deliver exceptional efficiency, durability, and gentle product handling. Available in a range of designs and high-strength engineered polymers to suit a broad variety of materials. The discs are designed for smooth passage through bends in the tubing circuit, and with clearances to the tube wall designed to eliminate or minimize product degradation. Their low-friction surfaces allow the discs to glide efficiently through stainless steel tubing, reducing material hang-up and allowing easy cleaning.

Drive wheels are equipped as standard with patented sprocket tips that can be replaced at up to 90 percent lower cost than one-piece sprockets. Each replaceable tip consists of two halves that bolt onto each spoke without the need to remove the sprocket, reducing downtime during maintenance. The tips also form a pick-up face having greater surface area and seating stability than the contact patch of one-piece sprockets, significantly extending cable life by reducing contact pressure between the slug and the spoke. Additionally, a wear indicator molded into the sprocket tip allows operators to easily identify when the tips need replacement, helping prevent wheel damage and subsequent harm to the cable-disc assembly.

An optional air knife can be located in the drive wheel housing to assist with dislodging material from the cable and disc assembly.

FLEXI-DISC CABLE AND TUBING

The FLEXI-DISC cable is offered in stainless steel with an optional polymer-coating. FLEXI-DISC straight tubing, elbows, and couplings are offered in 304 or 316 stainless steel with industrial or sanitary finishes, while clear inspection tubing can be located in any straight run of tubing to visually monitor conveyor performance.

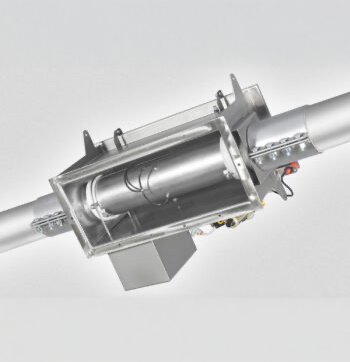

DRIVE SYSTEM

The Drive System powers a drive wheel that moves the cable and discs at a controlled, low speed throughout the conveyor circuit. The wheel is enclosed in a housing that can be provided with an extended design to prolong cable life by creating separation between material discharge point and drive wheel engagement. When equipped with the optional discharge cone, the Drive Wheel Housing can function as the primary or final discharge point—offering flexibility for your system layout.

Drive wheels are equipped as standard with patented sprocket tips that can be replaced at up to 90 percent lower cost than one-piece sprockets. Each replaceable tip consists of two halves that bolt onto each spoke without the need to remove the sprocket, reducing downtime during maintenance. The tips also form a pick-up face having greater surface area and seating stability than the contact patch of one-piece sprockets, significantly extending cable life by reducing contact pressure between the slug and the spoke. Additionally, a wear indicator molded into the sprocket tip allows operators to easily identify when the tips need replacement, helping prevent wheel damage and subsequent harm to the cable-disc assembly.

An optional air knife can be located in the drive wheel housing to assist with dislodging material from the cable and disc assembly.

AUTOMATIC CABLE TENSIONER

Engineered for performance and simplicity, the Cable Tensioner features a precision wheel that maintains optimal tension of the cable and disc assembly throughout the entire conveyor circuit.

The tubular cable conveyor tensioner is available in two models to suit different operational needs. The manual model allows for easy adjustment of the spring-loaded tension on the cable and disc assembly, ensuring consistent performance. For more advanced applications, the motorized model automatically adapts to dynamic loading conditions, optimizing tension in real time to extend cable life and reduce maintenance.

The tensioner housing features a clear cover that allows visual inspection of the interior of the tensioner in between maintenance and cleaning cycles. It also allows for quick visual confirmation of conveyor operation.

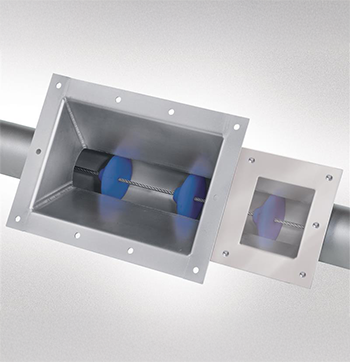

MATERIAL INLETS

Material inlets feature a modular design, allowing any number to be integrated into a tubular cable conveyor circuit. Each inlet includes anti-shear functionality to reduce breakage of delicate, friable materials, while a clear viewing window enables easy visual monitoring of pocket fill percentage.

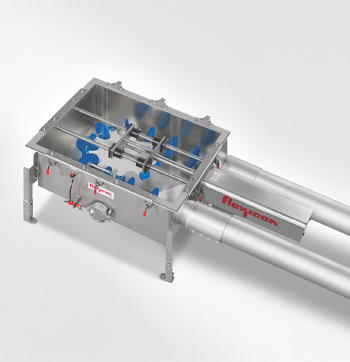

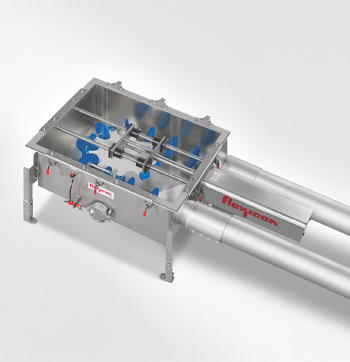

INLINE TUBULAR DISCHARGE VALVES

Inline Tubular Discharge Valves enable conveyor circuits to dispense material dust-free at one or multiple locations through round spouts for connection to a flexible downspout, or flanged outlets for connection to process or packaging equipment. Tubular Discharge Valves contain a U-shaped trough rotated by a pneumatic actuator, allowing complete material discharge at a mid-point of the conveyor, or total carry-over to a downstream outlet. With the trough in the downward (open) position, material discharges fully, with the assistance of standard air jets. Rotated 180° to the upward (fully closed) position, material continues along the conveyor.

INLINE FULL-FLOW DISCHARGES

Inline Full-Flow Discharges are devoid of valves and actuators, providing an unrestricted, final discharge through a flexible downspout or a flanged outlet of process or packaging equipment. An air knife can be employed in Inline Full-Flow Discharges to dislodge material from the cable and discs.

Tubular Cable Conveyors offer a range of advantages to improve your bulk handling processes.

The tubular cable conveyor is engineered to overcome material handling challenges that are often difficult to solve with other conveyor designs.

The tubular cable conveyor features a dynamic design that effectively adapts to the unique demands of any plant environment.

The functionality of the tubular cable conveyor enhances the productivity and efficiency of your process.

Tubular cable conveyors are well-suited for a variety of applications and plant environments. They can be paired with a broad range of upstream and downstream equipment including the Flexicon product line.

Tubular cable conveyors are an excellent choice for conveying short to long distances from manual bag dump stations.

Tubular cable conveyors are effective at conveying fragile and large particle size materials from bulk bags.

Tubular cable conveyors efficiently transport delicate and large particle materials from drums, boxes, and other large containers.

Tubular cable conveyors excel at delivering material to packaging lines, while maintaining the quality of fragile products.

Tubular cable conveyors are optimal for conveying materials such as coffee beans, almonds and peanuts to and from roasters.

FLEXI-DISC Conveyors are fully enclosed to prevent product and environmental contamination. At the end of a conveying cycle, the discs clear the conveyor tubing of material, virtually eliminating wasted product and facilitating rapid sanitation.

Flexicon can design your Tubular Cable Conveyor to meet your unique needs. Explore some of the configurations we have developed for customers like you.

Candy and Confectionary Products

- Todd Kish, Operations Manager at Quality Pasta Company LLC

Electric Products

– Marc Stassen, former GM of European Operations at Asbury Graphite & Carbon

How does the Flexicon® Tubular Cable Conveyor stack up against flexible screw conveyors and pneumatic conveying systems? Find out which one meets your application requirements.

"*" indicates required fields