Flexicon offers a range of bulk bag filling options, from simple stand-alone fillers to complete bulk bag filling lines including roller conveyors, pallet dispensers, and advanced automation controls. Designed to meet each customer’s specific budget and capacity needs, every filling solution is optimized for peak performance within its capacity range, ensuring maximum cost-efficiency.

Click and drag product to rotate.

Learn everything you need to know about Flexicon Bulk Bag filling systems.

Flexicon offers a range of bulk bag filling options, from simple stand-alone fillers to complete bulk bag filling lines including roller conveyors, pallet dispensers, and advanced automation controls. Designed to meet each customer’s specific budget and capacity needs, every filling solution is optimized for peak performance within its capacity range, ensuring maximum cost-efficiency.

Each Bulk Bag Filler model satisfies a distinct range of bulk bag filling applications and can be customized with performance enhancements to meet your individual requirements cost effectively. From basic, low-cost fillers to automated, high-capacity systems, Flexicon offers precisely what you need for bulk bag filling success.

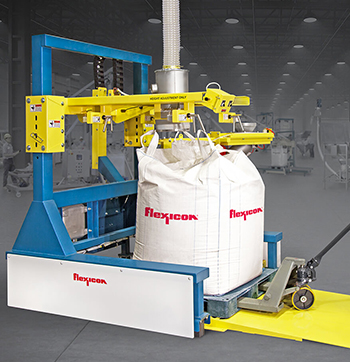

SWING-DOWN® BULK BAG FILLER

Flexicon’s SWING-DOWN® Bulk Bag Filler is the company’s most advanced filling station, engineered for medium- to high-capacity operations. Its innovative design lowers the fill head to floor level, allowing operators to connect bags more quickly, safely, and easily. This feature makes the SWING-DOWN® filler especially ideal for systems that include automated pallet handling and roller conveyors.

REAR-POST BULK BAG FILLER

REAR-POST fillers are intended for medium- to high-capacity applications. This fully-equipped bulk bag filling station is capable of satisfying most bulk bag filling applications and can be used with systems that include automated pallet handling and roller conveyors.

BASIC BULK BAG FILLER

For operations that do not require automated pallet handling or roller conveyors, the BASIC FILLER provides a cost-effective, lighter-duty alternative to the REAR-POST bulk bag filler—while still offering many of the same core features.

Flexicon offers various models of roller conveyors that can be configured to meet your specific layout and automation needs for a bulk bag filling operation. From integrated conveyors that streamline bag ejection and pallet placement, to powered systems that control the flow of materials, and gravity conveyors that offer simple, cost-effective transport—Flexicon delivers a complete range of solutions to enhance efficiency at every stage of your bulk bag filling process.

FILLING STATION ROLLER CONVEYOR

This powered conveyor is integrated with the bulk bag filler to automatically eject filled bags onto downstream conveyors. When paired with an upstream pallet dispenser, it can also position empty pallets beneath the filler, streamlining the filling process.

POWERED ROLLER CONVEYOR

These conveyors can be placed either upstream or downstream of the bulk bag filler. Upstream, they typically move pallets from the pallet dispenser to the filler in a controlled manner. Downstream, they manage the movement and precise placement of filled bags and accumulation of multiple filled bags within the roller conveyor system.

GRAVITY ROLLER CONVEYOR

Typically used in downstream accumulation zones or between powered conveyor segments, gravity roller conveyors rely on the weight of the load to move it forward. They provide a cost-effective solution for passive transport within the overall system.

PALLET DISPENSERS

A pallet dispenser in a bulk bag filling line automates the process of supplying pallets to the filling station, streamlining operations and reducing manual labor. By consistently delivering pallets at the right time and position, it enhances efficiency, minimizes downtime, and ensures a smooth workflow. This equipment also improves workplace safety by reducing the need for workers to handle heavy pallets, allowing for faster, more reliable production.

Explore our bulk bag filling system options, including:

Weighing and Load Cells

Integrated load cells can be incorporated into Flexicon bulk bag fillers for direct bag weighing, or paired with a pre-weigh hopper mounted above the filler. The pre-weigh hopper enables faster operation by pre-weighing material, allowing the next bag to be positioned while the hopper refills.

Controls and Automation

Bulk bag fillers can be equipped with programmable controls and human-machine interfaces (HMIs) that automate filling cycles and manage key parameters. These systems allow multiple fillers to operate independently or simultaneously, handling different products or bag types as needed.

Drum / Box / Container Filling

Bulk bag fillers can be configured to also fill drums, boxes, and containers. Other design enhancements for these applications include adjustable fill heads, built-in dust control, and automated indexing for multiple containers on a single pallet.

Pallet Jack Loading

Flexicon’s bulk bag fillers feature a low-profile design option, allowing filled bags to be easily removed using a pallet jack - eliminating the need for a forklift.

Sanitary Configurations

Sanitary bulk bag fillers are constructed from stainless steel and designed to comply with 3-A and USDA Dairy standards.Their continuous welds and NEMA-rated enclosures make them ideal for wash-down environments, while maintaining high standards of safety and operational efficiency.

Mobile Configurations

Designed with a compact, maneuverable frame, mobile bulk bag fillers can be easily positioned throughout the plant. Their portability enables flexible operation across multiple filling locations, minimizing the need for several fixed units.

Gravity Bulk Bag Filling

Weigh hoppers can be placed above a bulk bag filler to pre-weigh material before it is dispensed into the bag. This enables full bags to be removed and empty bags to be positioned while the hopper is filled with the next load of material, optimizing the filling process and enhancing accuracy.

Bulk Bag Filling Systems offer a range of advantages to improve your bulk handling processes.

Pneumatically retractable hooks partially suspend the bag during filling for superior bag shape, stability, and utilization of capacity. Upon completion of the filling of the cycle, bag loops are released either manually or automatically.

Air displacement outlet for connection to sock filter, cartridge filter, or dust collector (hidden by discharge spout assembly).

Material can be delivered to Bulk Bag Filler inlet equipped with variable flow control valve by Flexicon Flexible Screw Conveyor, Tubular Cable Conveyor, Pneumatic Conveying System, or directly from overhead storage vessel.

Concentric tubes comprising the discharge spout provide an annular gap through which air enters during bag inflation and exits during bag filling.

Inflatable collar holds and seals bag spout. Releases automatically as bag hooks retract.

The forklift fill head’s height adjustment accommodates bags of all popular sizes and features prominent fork tubes. Fork truck height comes standard, with an optional powered version available.

Load cells with overload protection transmit weight gain information to the system controller that starts/stops conveyors or opens/closes flow control valves.

Bag Inflation Blower

The bag inflation blower eliminates creases and pre-shapes bags, allowing material to fill corners for maximum bag stability during shipment.

Powered Fill Head Height Adjustment

Powered or forklift fill head height adjustment accommodates bags of all popular sizes.

Vibratory Deaeration/Densification Deck

Electric or pneumatic vibratory deaeration/densification deck operates with high amplitude and low-frequency motion. Inflatable air mounts lift the deck, isolating scale systems from vibration.

Coffee/Tea

- Erin Dall, President and COO at Mayorga

Electric Products

– Marc Stassen, former GM of European Operations at Asbury Graphite & Carbon

"*" indicates required fields

Flexicon bulk bag fillers (also known as FIBC, Big Bag and Jumbo Bag Fillers) are offered in a range of models to match the budget and capacity requirements of each customer’s application. They can be sold either as independent units or as components of a complete bulk bag filling system.

Roller conveyors are used in bulk bag filling lines to move empty pallets to the filling stations and transport filled pallets away from them.

Pallet dispensers automatically place empty pallets onto the roller conveyor to feed the bulk bag filling line.