Flexicon’s Bulk Bag Dischargers provide dust-free loading, untying, retying, and removal of bulk bags. Available in a range of configurations, including models with bag lifting frames for forklift loading and unloading, and those with cantilevered I-beams, electric hoists, and trolleys for handling bulk bags without the need for a forklift.

Click and drag product to rotate.

Learn everything you need to know about Flexicon Bulk Bag Dischargers.

BULK-OUT® Bulk Bag Dischargers

Flexicon’s BULK-OUT® Bulk Bag Dischargers – also known as FIBC, Big Bag, or Jumbo Bag unloaders are available in a wide range of frame configurations to suit various operational needs. Each model can be customized with innovative accessories and integrated flow-promotion devices to ensure efficient, dust-free, and reliable material discharge.

Engineered for strength and long-term durability, Flexicon’s discharger frames provide stable support for bulk bags throughout the unloading process. Available in rugged carbon steel with industrial-grade finishes or corrosion-resistant stainless steel, these frames are built to meet the demands of industrial, food, dairy, and pharmaceutical applications.

FLOW PROMOTION

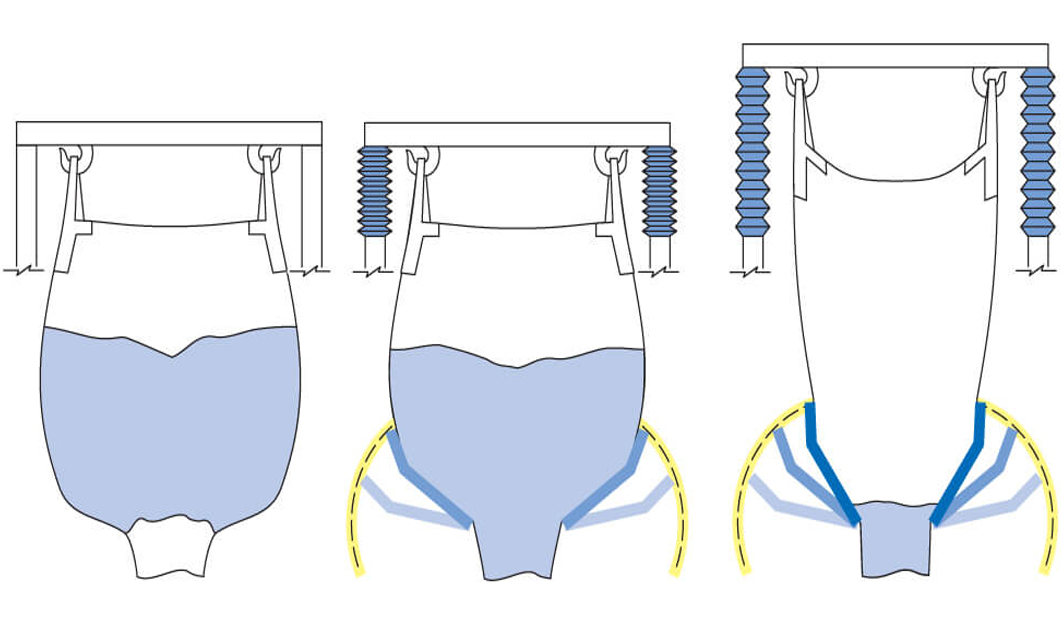

Flexicon bulk bag dischargers feature advanced flow promotion devices that stretch bags during emptying, actively massage bags to ensure smooth material flow, and provide efficient spout connections for consistent, uninterrupted discharge.

BAG SPOUT INTERFACE

Flexicon’s advanced bag spout interface creates a dust tight seal throughout every stage of bulk bag unloading including untying, discharging, retying, collapse, and removal, ensuring clean, efficient, and safe operation in demanding industrial environments.

SPOUT-LOCK® clamp ring eliminates dust during untying, discharge, bag collapse and removal

The SPOUT-LOCK® clamp ring forms a sealed, high-integrity connection between the clean side of the bag outlet spout and the TELE-TUBE® telescoping tube, preventing contamination and dust release during untying, discharge, bag collapse, and removal. This secure interface allows safe drawstring release for dust-free material flow into the hopper, while quick-release handles ensure fast, tool-free spout connections. By maintaining a sealed system, SPOUT-LOCK® often eliminates the need for flow control valves, except when retying partially emptied bags.

TELE-TUBE® telescoping tube prevents dead spots and promotes flow

The TELE-TUBE® telescoping tube raises the SPOUT-LOCK® clamp ring for connection to the bag spout, then lowers to maintain continuous downward tension. As a result, the spout is kept taut at all times, preventing excess spout material from bulging outward (creating dead pockets) or falling inward (creating flow restrictions). Works in conjunction with the SPOUT-LOCK® clamp ring and FLOW-FLEXER® bag activators to promote material flow and total evacuation. Available USDA accepted.

Leak-proof retying of spouts with POWER-CINCHER® flow control valve

Unlike opposing bars that pinch the spout of partially empty bags from two sides, the POWER-CINCHER® pneumatically-actuated flow control valve contains a series of curved, articulated stainless steel rods that cinch the spout concentrically on a horizontal axis for easy tie-offs, and vertically in a tight zigzag pattern to prevent leakage of even the finest powders. It also resists jamming, breaking and leaking, and allows full-open discharge from bag spouts of all popular diameters. Available USDA accepted.

Conventional Iris Valves Also Available

When a sealed connection isn’t necessary, iris valves offer a reliable solution. The bag outlet spout is pulled through the valve, which is then closed around the spout to prevent premature material flow during untying of the bag. Once the spout is untied and the access door is closed, the valve is gradually opened to initiate controlled material flow into the hopper.

TELE-TUBE® telescoping tube prevents dead spots and promotes flow

The TELE-TUBE® telescoping tube raises the SPOUT-LOCK® clamp ring for connection to the bag spout, then lowers to maintain continuous downward tension. As a result, the spout is kept taut at all times, preventing excess spout material from bulging outward (creating dead pockets) or falling inward (creating flow restrictions). Works in conjunction with the SPOUT-LOCK® clamp ring and FLOW-FLEXER® bag activators to promote material flow and total evacuation. Available USDA accepted.

FLOW-FLEXER® Bag Activators

Pneumatically-actuated FLOW-FLEXER® bag activators ensure efficient material flow by compressing the bottom edges of the bag at timed intervals. This action directs contents toward the outlet spout, promoting complete and consistent evacuation of material.

POP-TOP™ BAG STRETCHING DEVICES (BFF models only)

As the bag empties, POP-TOP bag stretching devices pull upward on the four corners of the bag promoting a “V” shape enhancing flow of bulk materials.

Flexicon bulk bag dischargers are built for strength and durability, with heavy-duty frames that securely support bulk bags throughout the discharge process. Constructed from rugged carbon steel with industrial-grade coatings for long-lasting performance, or stainless steel for applications requiring sanitary compliance or resistance to corrosive or harsh environments, these frames deliver reliable operation for demanding conditions.

QUICK SHIP

![]()

STANDARD EQUIPMENT

OPTIONAL EQUIPMENT

Flexicon’s bulk bag dischargers feature a sealed system that maintains dust-free operation at every stage of the discharge cycle. From untying bag spouts to retying partially emptied bags and collapsing empty bags, the system ensures clean, contained handling.

High-integrity connection between bag outlet spout and discharger.

The SPOUT-LOCK® clamp ring forms a secure, dust-tight seal between the clean side of the bag spout and the clean side of the TELE-TUBE® telescoping tube. Once connected, the bag’s drawstring can be released, allowing material to flow freely into the hopper—quickly and without dust

BAG-VAC® dust collector collapses empty bags prior to tie-off.

The sealed connection can be vented through a filter sock, a central dust collection system, or Flexicon’s optional BAG-VAC® dust collector. Activating the BAG-VAC® creates negative pressure within the sealed system, collapsing empty bags before tie-off and eliminating dust typically released during manual flattening. It also vacuums particles trapped in spout creases during disconnect, removing the need for awkward access ports.

Flexicon’s bulk bag dischargers can be configured to suit a wide range of unique applications, offering flexible design options to meet specific material handling requirements and operational environments.

Optimize transfer of materials from bulk bags to downstream equipment or containers with Flexicon's customizable bulk bag dischargers. Our engineered frames ensure reliable gravity-fed operations, with optional access platforms for applications requiring elevated heights.

Maximize efficiency in tight spaces with Flexicon's low-headroom bulk bag dischargers. From compact, custom-designed frames to innovative split-frame designs that allow easy bag loading without requiring fork truck masts to extend above the frame, these dischargers are perfect for constrained headroom environments.

Effortlessly handle highly solidified materials with Flexicon's bulk bag dischargers, featuring integrated hydraulic conditioning rams to loosen compacted contents for complete discharge. Although Flexicon offers standalone conditioners, this space-saving design can enhance operational efficiency.

Enhance versatility with the Multi-Purpose Hood, available for all Flexicon bulk bag dischargers. This innovative option enables automatic discharging from bulk bags and manual emptying from sacks, drums, and other containers. Pair it with an optional dust collector to maintain a clean, dust-free plant environment.

Total Dust Containment

Flexicon bulk bag dischargers deliver total dust containment with these precision-engineered features:

Bulk bag dischargers are well-suited for a variety of applications and plant environments. They can be paired with a broad range of equipment including the Flexicon product line.

Bulk bag dischargers provide a controlled, dust-tight feed into flexible screw conveyors for efficient, short- to medium-distance material transfer.

Bulk bag dischargers integrate with pneumatic conveying systems to deliver high-throughput, dust-free transfer of powders and fine materials.

Bulk bag dischargers ensure enclosed, spill-free loading into tubular cable conveyors for smooth, contamination-free transport of friable materials.

By conditioning compacted bulk bags, bulk bag dischargers work with bulk bag conditioners to ensure consistent flow and minimize downtime.

Bulk bag dischargers provide accurate, consistent feed to weigh batching systems, supporting precise ingredient measurement.

Flexicon can design your bulk bag discharger to meet your unique needs. Explore some of the configurations we have developed for customers like you.

Food Products Machinery

– Hiram Carlo, Plant Manager at Sazon, Inc., a manufacturing division of GOYA Foods

Food Products Facilities

– Jean-Paul Amyot, Packaging Workshop Manager at Tereos

"*" indicates required fields