With more than 25,000 installations worldwide, Flexicon’s® Flexible Screw Conveyors effectively convey virtually any bulk material, including both free-flowing and non-free-flowing.

The versatile design allows for horizontal, vertical, or inclined configurations, with the ability to navigate around obstacles, making them adaptable to various plant layouts and process requirements.

With only one moving part, flexible screw conveyors ensure efficient, reliable performance with low maintenance for any manufacturing operation.

Click and drag product to rotate.

Learn everything you need to know about Flexicon® Flexible Screw Conveyors.

A Flexicon® Flexible Screw Conveyor features a helical steel screw enclosed within a tube with no internal bearings or seals in the material contact zone. An electric motor at the discharge end drives the screw, efficiently propelling material to its destination.

Versatile Intake Option

The intake end of a flexible screw conveyor tube that features a charging adapter that connects to a hopper, bulk bag discharger, bag dump station or other process equipment. A variety of vibratory and mechanical flow promotion devices are available to move non-free-flowing material into the conveyor’s charging adapter.

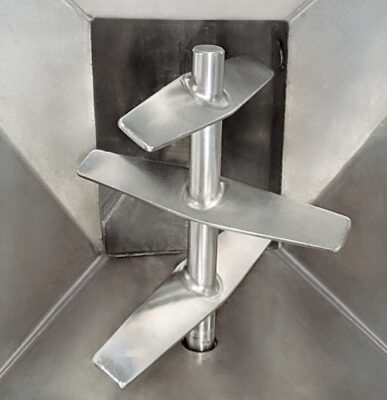

RUGGED FLEXIBLE SCREW

The rugged flexible screw is the only moving part contacting material, moving free-and non-free-flowing materials that tend to pack, cake or smear, with no separation of blended products. Designed to be run at 100% fill capacity, its self-centering design ensures efficient, damage-free flow, accommodating particle size and fragility.

ENCLOSED CONVEYOR TUBE

Flexible plastic, rigid plastic, or carbon/stainless steel tubing can be routed at any angle, with an enclosed system to contain dust. The conveyor’s clean-out cap allows quick emptying and wash-down, while its design eliminates material contact with seals or bearings, making the flexible screw the only moving part in contact.

Efficient Conveyor Drive

Compact enough to fit in tight spaces, the flexible screw conveyor discharge end can be suspended on chain or cable, attached to a ceiling support, or affixed to process equipment or the rim of a vessel. The screw is driven above the point at which material is discharged, preventing material contact with bearings or seals.

Explore our flexible screw conveyor options, including mobile units, custom configurations, sanitary solutions, flow promotion features, and hoppers, all designed to enhance efficiency and meet your specific material handling needs.

Mobile Unit Configurations

All Flexicon flexible screw conveyors are available on caster-mounted frames with conveyor support masts for in-plant mobility allowing you to gain the benefit of handling materials throughout your plant.

Screw Geometry

Bulk materials come in all shapes, sizes, flow properties and bulk densities. Flexicon offers a wide range of screw geometries to handle them all. Whether the material packs, cakes, smears, plugs, fluidizes, or interlocks, Flexicon has you covered.

Hoppers and Flow Promotion

Hoppers – A wide range of hopper sizes and designs are available to feed the flexible screw conveyor’s charging adapter.

Hopper Flow Promotion – Flexicon offers hopper wall vibration devices, mechanical agitation paddles, or material aeration pads to assist with the flow of the most difficult materials.

Flexible screw conveyors offer a range of advantages to improve your bulk handling processes.

Economical and Simple

A Flexicon® Flexible Screw Conveyor offers an economical solution for purchasing, installation, and operation by eliminating the internal and external components that often make other conveyors expensive and complex. It's only moving part in contact with the material is a durable, flexible screw that resists wear and fatigue, ensuring exceptional reliability and minimal maintenance. The flexibility of the screw and tube allows for easy routing in any direction, enabling custom intake and discharge placement in situations that would be challenging, costly, or impractical with other conveyor systems.

One Moving Part

The only part contacting material in a Flexicon® Flexible Screw Conveyor is the durable flexible screw driven by an electric motor. As it rotates, the screw propels material while self-centering within the conveyor tube, maintaining constant clearance from the tube wall. This streamlined design eliminates the need for cables, chains, disks, internal bearings, and other moving parts commonly found in bucket elevators, rigid augers, drag chains, and/or aero mechanical conveyors — parts that can add initial cost, require maintenance, wear out, increase contamination risk, and/or are prone to breakdowns.

HIGH-RELIABILITY, LOW MAINTENANCE

A Flexicon® Flexible Screw Conveyor is designed for reliable, low-maintenance operation, with no internal bearings, cables, filters, chains, buckets, or other potentially problematic components that could wear out, break down, or require maintenance. The only moving part in contact with the material is a rugged flexible screw driven by an electric motor. Even under a full load of moist, dense product – depending on the application parameters - a Flexicon flexible screw conveyor can start and stop repeatedly without binding or damage to the unit. This combination of durability and flexibility boosts productivity and ensures smooth, dependable performance, while significantly reducing maintenance demands.

Convey in Any Direction

Unlike many conveyors with limited incline angles and/or straight-only conveying paths—such as rigid screw conveyor, bucket elevator, drag chain conveyor, and aero mechanical conveyor designs—Flexicon® Flexible Screw Conveyors offer exceptional versatility, transporting material vertically, horizontally, or at any angle. It can easily navigate over, under, or around obstacles and pass through small openings in walls or ceilings, providing a flexible, space-saving solution for a wide range of conveying applications.

Gentle Product Handling and Blending

Flexicon® Flexible Screw Conveyors are designed to handle products gently. The self-centering screw rotates while maintaining ample clearance from the tube wall to prevent grinding, crushing, and other potential damage. The screw’s gentle rolling action not only ensures smooth, optimized control, but also preserves the integrity of blends, preventing separation throughout the entire length of the conveyor.

Enclosed Tube Prevents Contamination

A Flexicon® Flexible Screw Conveyor is completely enclosed, ensuring a dust-free and mess-free operation that prevents contamination of both your bulk products and plant environment, while preserving the moisture and temperature levels of the materials being conveyed. With its smooth interior surfaces, free of the potential contamination points found in other conveyor designs, the flexible screw conveyor is especially well-suited to maintaining the purity of your bulk material.

Fast, Thorough Cleaning

With no internal cracks, crevices, or bearings to trap particles or hinder cleaning, the flexible screw conveyor allows for quick and thorough sanitation by simply removing the clean-out cap, reversing the screw to evacuate residual material, and flushing with air, water, steam, or a cleaning solution.

Meet Cleanliness Standards

Flexicon® Flexible Screw Conveyors, along with most other Flexicon equipment, are available in carbon steel with a variety of durable industrial finishes or in stainless steel. They can be finished to meet industrial, food, dairy, or pharmaceutical standards, including designs constructed for 3-A Compliance.

Flexible screw conveyors are well-suited for a variety of applications and plant environments. They can be paired with a broad range of upstream and downstream equipment including the Flexicon product line.

Flexible screw conveyors are an excellent choice for conveying short to medium distances from manual bag dump stations.

One of the most popular applications for a flexible screw conveyor is the unloading of bulk bags.

Flexible screw conveyors are a simple solution for elevating material from mid-sized bulk containers.

When the accuracy of a gravimetric feeder is not required, a flexible screw conveyor can be used to meter bulk material into your process.

Whether handling single or multiple ingredients, flexible screw conveyors are ideal for accurately metering material to or from a scale system.

Due to their flexible routing capabilities and compact inlet design, flexible screw conveyors are perfected suited for direct integration with other processing equipment such as blenders, screeners, and size reduction equipment.

With their high-reliability and ability to start and stop repeatedly under full-load, flexible screw conveyors are an ideal choice for consistently feeding material into packaging lines and refilling volumetric or gravimetric feeders.

Flexicon can design your flexible screw conveyor to meet your unique needs.

Explore some of the configurations we have developed for customers like you.

Food Products Machinery

– Hiram Carlo, Plant Manager at Sazon, Inc., a manufacturing division of GOYA Foods

Candy and Confectionary Products

– Marc de Faye, Maintenance Manager at Theo Chocolate

How does the Flexicon® Flexible Screw Conveyor stack up against pneumatic and tubular cable conveying systems? Find out which one meets your application requirements.

"*" indicates required fields